I used image 50302a from chapter 3 as inspiration for my quilting lines in this chapter.

|

| 50501 |

Wadded Quilting with fine polyester knitted fabric (swimwear lining) over cotton wadding using running stitch.

|

| 50502 |

Wadded Quilting with fine polyester knitted fabric over shredded newspaper using running stitch. Newspaper exposed at edges as design feature.

|

| 50503 |

Wadded Quilting with nylon net over feathers, using running stitch.

|

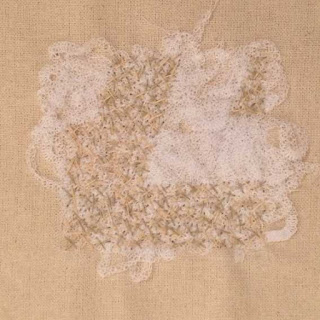

| 50504 |

Wadded Quilting with nylon net over threads run through the overlocker. Whole shapes have been filled with random, overlapped cross stitches.

|

| 50506 |

Shaped Quilting with silk habotai over 'funky foam' shapes. Stitched with chain stitch.

|

| 50507 |

Shaped Quilting with nylon net over pumpkin seeds. Stitched with rows of horizontal straight stitches. I originally used a straight running stitch for this sample, but thought the parallel rows of stitch was far more characterful and contemporary and contrasted well with the smooth rounded texture of the seeds that are visible under the net.

|

| 50508 |

Padded Quilting with fine polyester knitted fabric. Stitched with twin needle on sewing machine & stuffed from the back with polyester stuffing. Think this might be slightly overstuffed as shapes have been distorted, but I guess the distortion could also be used to creative effect. This is the first time I've ever really played with the twin needle. I found that the flat area between the two rows of stitching contrasted well with the puffy, overstuffed areas.

|

| 50509 |

Padded Quilting with silk organza. Stitched from the back with herringbone stitch (to give a double row of running stitches on the front), and threaded with sari silk. I really enjoyed this sample. Its very neat and precise and was much easier to control than I had imagined.

|

| 50510 |

Corded Quilting with silk habotai. Lengths of string were stitched between channels of 'twin needle' machine stitching. I have ordered a pin tuck foot for my machine as I think it would make it easier to control the direction of the string during this process.

|

| 50511 |

This is the previous sample from the back. I think this is much more attractive, probably because of the contrasting shades and the contrasting textures of the rough string against the soft shiny silk. It would have probably been quite interesting to do a combination of backwards and forward facing channels.